At Lesters Packaging, we believe that packaging should be driven by innovation and thoughtful design. That’s why we’ve created a simple yet powerful five-step process to turn your bespoke packaging ideas into reality, delivering more guidance, more quality, and more peace of mind every step of the way.

1. Your Brief: Listening to Your Vision

Every partnership starts with a conversation. You share your project requirements, specifications, budget, and overall vision… and we truly listen. Whether you need heavy-duty packaging or retail-ready packaging, this initial briefing ensures we fully understand your goals before moving forward.

2. Consultation: Professional Guidance Tailored to You

Once we’ve understood your brief, we set up a one-to-one consultation with one of our specialists. During this session, we’ll:

- Recommend the ideal materials (corrugated, board-laminate, foam-lined, or eco-friendly options)

- Advise on structural design best practice (weight, stacking, moisture-protection)

- Share creative insights on finishes, printing, and branding touches

Our goal is to align your vision with our expertise, leaving you confident in the direction we’ll take together.

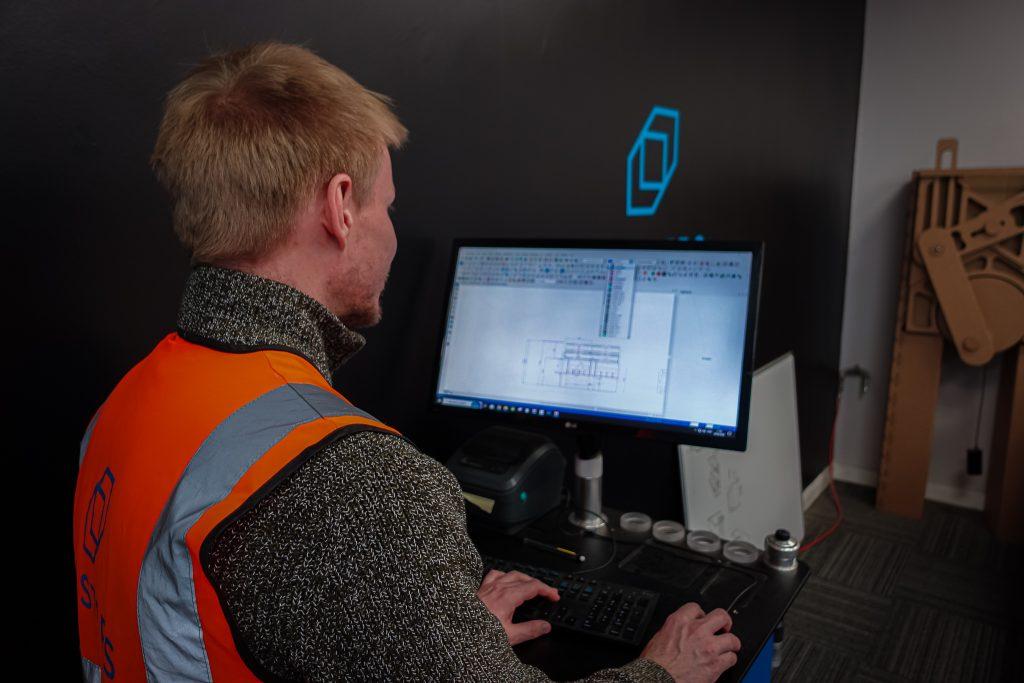

3. Concept & CAD Design: Seeing It All Come Together

Now we’ve got all the consultation notes, our in-house design team creates initial concepts and technical CAD drawings. Using state-of-the-art software, we model every dimension, fold-line, and joint, giving you a crystal-clear preview of how your bespoke packaging will look, perform, and be assembled.

4. Sampling & Testing: Quality You Can Hold

Drawings are great, but nothing beats a real mock up. We produce physical prototypes, complete with your branding and structural elements, for you to test in your own environment.

You’ll verify:

- Fit and finish (does your product slide in and stay secure?)

- Functional performance (stacking strength, lid closure, handle ergonomics)

- Print clarity and material feel

Only once you’re 100% satisfied with the sample do we move on to full production.

5. Production & Delivery: Quality Assurance Every Step

With your approval in hand, we roll into production at our UK-based facility. Every carton, box, or shuttle pack is manufactured under strict quality-control protocols and packed for safe transport. We co-ordinate logistics so that your bespoke packaging arrives on time and in perfect condition, ready for you to use or distribute.

Why Choose Lesters Packaging?

At Lesters, we don’t just deliver packaging – we Deliver More:

- More guidance: Expert consultation from day one.

- More quality: Rigorous sampling and QA ensure flawless performance.

- More peace of mind: Timely delivery and ongoing support.

Explore our full suite of bespoke and standard solutions at packaging solutions or browse our product range to see what’s possible.

Ready to elevate your packaging? Get in touch today and let Lesters Packaging help you Deliver More.